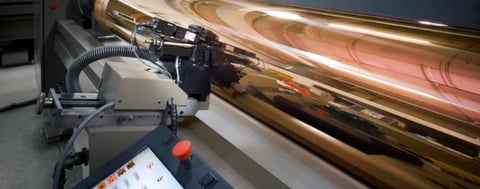

Gravure Print Cylinders

VIEW SPECIFICATIONS

Gravure Cylinders That Deliver More Than Just Ink

Precision Roll Solutions manufactures gravure print cylinders that are engineered to meet the most demanding print, coating, and decorative applications — from flooring and films to tissue, medical packaging, and technical laminates.

With electromechanical engraving, copper plating, and chrome finishing, our gravure rolls ensure unmatched clarity, consistency, and performance across multi-station processes.

Trusted By:

Consumer and medical packaging converters, pharmaceutical manufacturers, film processors, industrial coating operations, decorative surface producers, and more.

- Micron-accurate engraving for lifelike reproduction

- Copper, nickel, and chrome plating options

- Supports metering, bonding, and image printing

- Compatible with OEM or legacy equipment

- Engineered for printed or coated medical, pharmaceutical, hygiene, and food-grade substrates

- Re-engraving and rechroming services

- Journal repair and precision rebalancing

- Full restoration of legacy or damaged cylinders

- Support for all major OEM roll specs and tolerances

- Fast lead times from our U.S. manufacturing facilities

- North America’s largest tool library

- Engineers and technical sales that understand your press, substrate, and regulatory needs

- Gravure rolls built to deliver consistency, compliance, and performance

SPECIFICATIONS

- Standard cylinder lengths up to 130” and diameters up to 36”

- Custom sizing available

- Gravure cell depths up to 90 microns for high-volume ink transfer, adhesive laydown, and specialty coatings

- Compatible with all standard and custom press configurations

- Precision-balanced for high-speed applications

- Engraving options for fine, medium, or deep cell geometry

- Customizable patterns for ink laydown, bonding, or coating targets

- Copper, nickel, and chrome plating options

From engineering to engraving and balancing, PRS controls every step of the gravure cylinder design and manufacturing process to ensure precise specs and repeatable performance under demanding conditions.

Connect with

PRS Experts

Questions? Tough challenge? Need a second opinion? The PRS experts are here to guide you to your next-level engraved or precision roll solution. Set up a consultation today!